Showroom

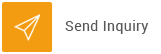

Mounting Machine are used to enclose the specimens of a

ceramic, metal and other material. These machines are helpful in the sample preparation

and simplify the process of analysis. These are responsible for the protection

of many coated and fragile items.

Portable Model Handysurf can perform the measurement in

different positions. This is apt for both vertical as well as overhead

surfaces. This is used to transfer the measured data, profile curves and other

parameters directly to the PC.

Metallurgical Image Analyzer is a new generation analyzer

that perform the image analysis of Software. This is useful for the

Metallurgists as it helps them to do the analysis in the simplex way. It is

accessible with a single screen window based system and is flexible in use.

independent to

The Weld Penetration

Inspection System is a windows based imaging application, which provides state

of the art imaging solutions and can function as an easy to use tool. It can

handle the things in an effective way. The software is configured with the

welding-cross section measurement.

|

QS METROLOGY PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |